Incuded in this delivery is a 'made to measure' CNC panel saw along with a number of our heavy duty 'X' type machines.

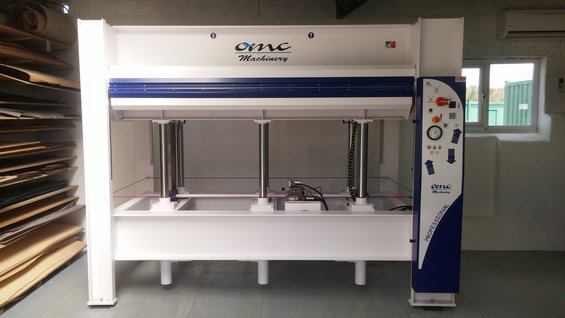

Pressing ahead......2 x OMC hydraulic veneer presses installed in Wiltshire...

A Wiltshire based high end furniture maker recently orderd 2 new OMC 8ft x 4 ft hydraulic presses. The machines were ordered to customer specification, both having a pressing capability of upto 90 tons, one with a 450mm opening and the other a 650mm. Both machines were equipped with parallel safety control to ensure the platen always remains level and in the event of incorrect loading which stop the machine going to high pressure and eliminate the possibility of damage to the platens.

The machines are built at the OMC factory just outside of Bergamo in Italy with the frames being made out of structural steel. These particular machines were also manufacturerd in preparation to allow them to be converted to heated presses should the need ever arise and from point of order to delivery took just 5 working weeks.

Delivery was somewhat of a challenge as the customer already had 2 x heated 10ft x 5ft presses, one of which had to be moved down 2 x steps to reorganise in readiness for the new machines, the other we had to remove from site, taken as a part exchange against the new machines.

The workshop where the new machines were to be delivered were part of a farm, so delivering 2 machines weighing 4 tons and removing one reputably weighing 10 tons was no mean feat...!

Check out how the job went....and what we do...

Moving one machine down 2 steps in preparation for the new machines.

Part exchange machine being moved in preparation for collection...note the headroom..the machine had to be carefully manouvered between the rafters of the roof, steadily moved through 90 degrees towards the exit door.

New Machines arrive on a 40ft articulated wagon complete with hiab for offloading.

Manoevering around the farm buildings...fantastic work by Andy at Chris Bennetts

Peekaboo.....carrying out what appears to be the impossible....even the 4 legged friend was impressed......and please note...no animal was hurt during the delivery of these machines :-)

Remote and independent steering to the trailer unit make the impossible possible...

Almost there...

offloading....

It's a tight fit....

just millimetres to spare....

First machine in position..

2nd machine in position....

Finally, out with the old....again, very tight on headroom..

Up and away....job complete...

This is just a typical example of the service we provide.

Other posts

From the Genisis P32 to the top of the range Genisis X3 Plus, the Genisis range of sliding table panel saws still offer unbeatable quality, reliability and value for money...

Our super popular hot melt edge banding machines are still proving to be a popular choice.....throughout the UK...

Southport based DPI invest with AES on a heavy duty high speed CNC router...

We now have available from stock a large selection of sliding table panel saws including the compact Genisis XC...